Sensor Data Reporting

The MTS160 measures and reports in real-time several parameters relative to the tracks and position markers. New data is evaluated at 200Hz, or every 5ms.

Continuous Dual Track Detection

The MTS160 always reports data of two tracks simultaneously: One data set for Left and one for the Right track. This happens even if only one track is present. In that case, the data for the Left and Right tracks are identical. This scheme greatly simplifies and improves the handling of merges and forks and is discussed further below.

Track Detection and Strength

The sensor will detect and report the presence of a track and its strength using two bits.

| Value | Track Detection | Magnetic Strength |

|---|---|---|

| 0 | No Track | - |

| 1 | Track Present | Weak |

| 2 | Track Present | Medium |

| 3 | Track Present | Strong |

The sensor operates correctly whenever a track is detected, regardless of the magnetic strength. It is, however, strongly recommended to always have a Medium or Strong level at all locations around the path.

TIP

If the magnetic strength is minimal, consider lowering the sensor closer to the track, or/and use magnetic tape with higher magnetization.

Lateral Tracks Positions

The sensor reports the lateral position of the tracks relative to the center of the sensor. Values are in millimeters. Positions left of the center are negative values. Positions right of the center are positive values.

Tape Incidence Angles

One of the MTS160’s unique capabilities is the measure of the track’s incidence with the sensor. This enables the robot to distinguish between going off track, and therefore the need to apply only small trajectory corrections and entering a curve and therefore needing to apply sustained steering.

The sensor reports the incidence angle of each track with a 1-degree resolution.

Forks and Merges

The MTS160 supports a very effective forks and merges management technique that ensures precise and smooth, jolt-free, transitions.

It is based on the fact that the sensor always sees two tracks simultaneously, even if only one track is actually present.

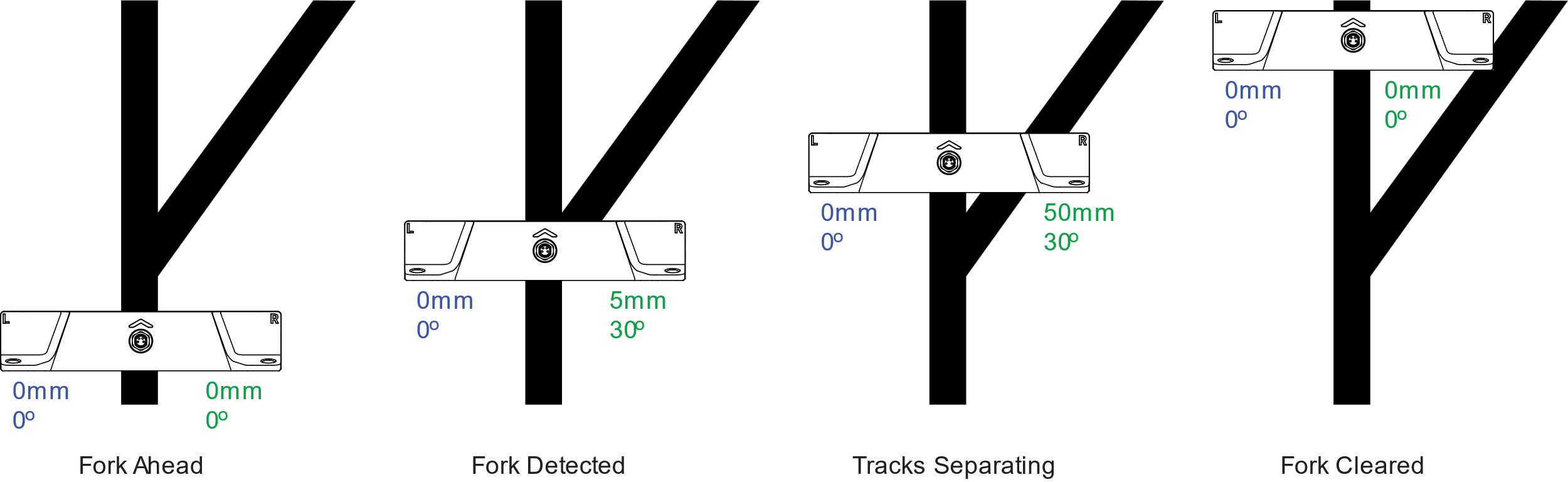

When approaching a fork, and the sensor is over a single track, it will report two positions and two angle values. Assuming the robot is perfectly centered and aligned with the track, these will be 0mm and 0 degrees.

When entering the fork, the second track begins to register, and its position and angle are measured and reported. Depending on which branch the robot needs to follow, the navigation computer will use the left or the right track information for steering.

Assuming the left track is followed, the right track information will be ignored as the branches separate.

After the fork is cleared, the sensor only sees a single track again and the left and right values are identical again.

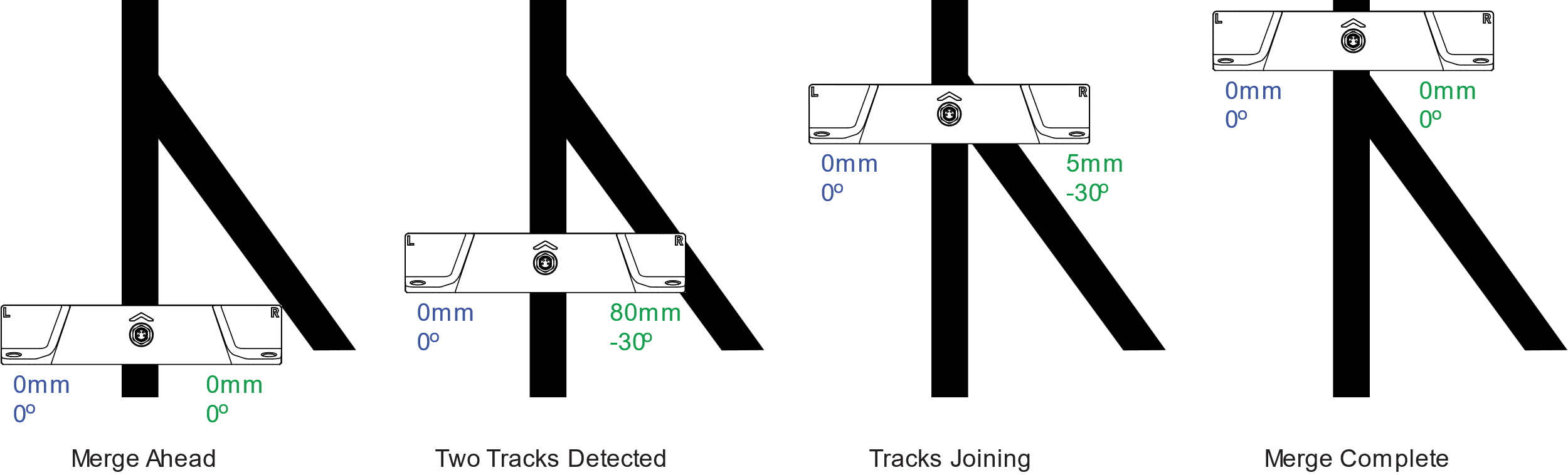

Merges also use the fact that two position values are reported. Prior to entering a merge, the navigation computer must be set to follow the track that is opposite to this of the incoming branch. In the example below, the robot must be following the left track. As the robot progresses it will suddenly detect the track that is branching from the right, which it will simply ignore until the merge is complete.

WARNING

Beware that if the robot is set to follow the right track, it will abruptly steer to follow the right track as soon as it is detected.

Left and Right Position Markers

Markers are special bits of magnetic strip that have the opposite polarity to the main track. They are typically used to identify special locations along the robot’s path. For instance, markers can indicate a fork ahead in the path, or a merge. They can tell the robot when it's approaching a charging station, or if it needs to adjust its speed, to either pick up the pace or slow down for safety.

The sensor can detect and report the presence of a Left Marker on the left side of the track, or a Right Marker one on the right side. Markers can be combined into patterns to uniquely identify more locations along the track.

It is recommended to use 25mm or longer markers. Markers that are too short will not have enough surface to ensure strong adherence to the floor. Markers shorter than 25mm may also have insufficient magnetic strength.

While markers must have a minimal length to be physically detected by the sensor, their presence will be reported to the PLC or Navigation Computer as they appear and disappear. Left and Right markers need to be longer as the robot moves faster or/and if their position is read at a lower frequency. This restriction does not apply to Navicode coded markers as these are decoded within the sensor.

It is recommended to place the markers so that their edge is 20 to 30mm away from the edge of the main track. The sensor reports the lateral position of markers when detected.

When two markers are on the same side, spacing between them should be 50mm for their magnetic fields to be distinct from one another.

Last-Millimeter Magnetic Point-Source

Another unique capability of the MTS160 is the detection along the X and Y axis of point-source disk magnets with millimeter accuracy. By installing one such magnet at a precise known location on each side of the track, it is possible to evaluate the robot’s exact position and orientation with very high precision.

TIP

This feature makes the sensor a valuable accessory for last-millimeter positioning on robots using laser or vision navigation.

Magnetic disks must be of opposite magnetic polarity than this of the main track. The sensor therefore detects them the same way as regular markers. In addition, the sensor will report their X and Y position.

Adhesive point-source magnets can be ordered from Naviq.

Navicode Coded Markers

The MTS160 sensor is designed to detect and decode specific combinations of left and right markers, utilizing a simple and efficient coding scheme. This scheme encodes data using basic patterns for binary values 1 and 0, which can be concatenated to form multi-bit numbers.

Decoding begins when the sensor detects a marker on either the left or right side. The process continues as long as a marker is present on one side or the other. The decoding is completed, and the captured value is stored when no marker is detected on either side.

Navicode always starts with the bit value 0 and is terminated by an end marker. These ensure that a code can be detected and read correctly regardless of the orientation and travel direction of the robot.

Navicodes can range from 1-bit to 16-bits in length. Once a code is successfully detected and recognized, its value is stored in a register, accessible via serial communication or CANbus. Additionally, an 8-bit counter increments with each recognized code, which can also be read through the same communication channels.

TIP

The navigation computer or PLC can monitor this counter to identify when a new marker is detected and subsequently send a command to retrieve the code's value.

A Navicode pattern generator is available on the Naviq website. This tool will create an image of the marker elements’ arrangement based on a user-entered value.

Internal Sensors Self-Test

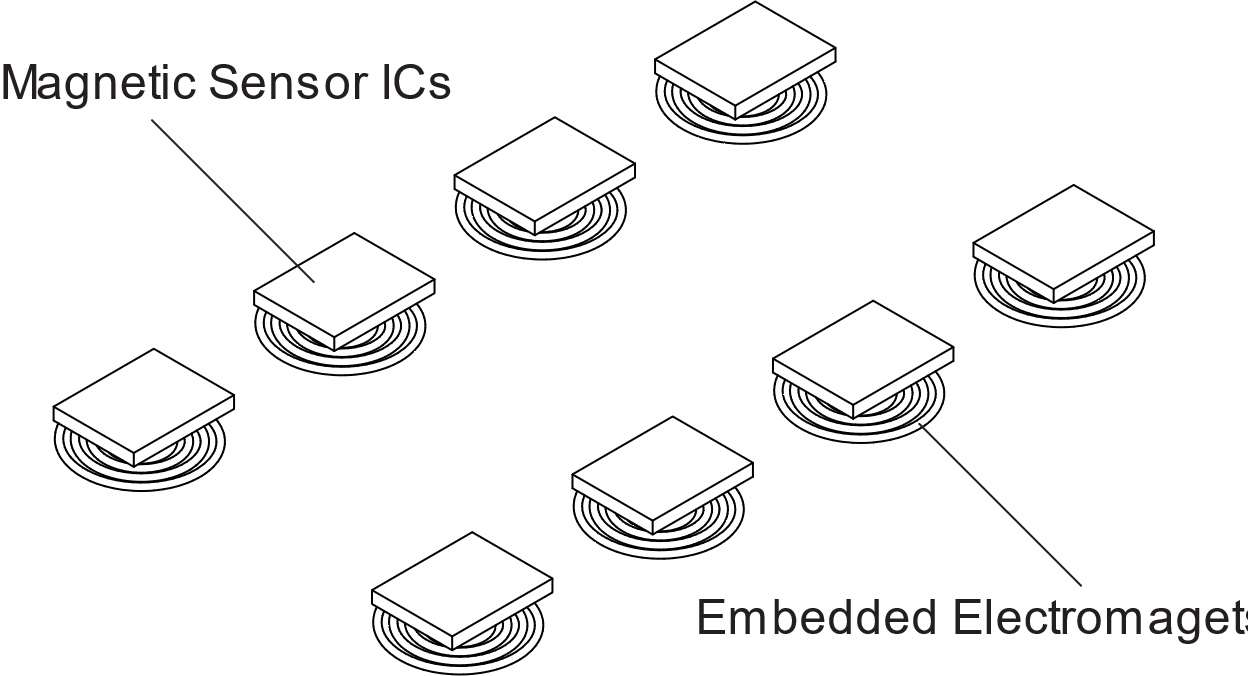

The MTS160 magnetic guide sensor features a Naviq-patented innovation that uses integrated electromagnets to periodically perform a self-test on each of the 32 internal sensor ICs.

This self-test is automatically conducted each time the sensor is powered on or when a command is issued via USB, Serial, or CAN interface.

During the test, the coils are energized to generate a magnetic field directly beneath each sensing element. The MCU then verifies that the output of each internal sensor changes by a value within the expected range. If any sensor fails to detect a change, or if the detected change falls outside the valid range, the test fails.

The results of the self-test are stored in three registers, which can be accessed at any time through the same communication channels.

The registers contain the following information:

Fail/Pass Status: A value of 1 indicates the test failed, while 0 indicates a pass condition

Minimum Field Difference: The smallest change in the magnetic field detected by any of the sensors.

Maximum Field Difference: The largest change in the magnetic field detected by any of the sensors.

If the test fails, the specific type of fault can be determined, although the test does not specify which of the 32 internal sensor ICs failed.

In the event of a failure, the two RGB LEDs will flash red to provide a visual indication of the fault.

The complete test sequence takes approximately 30 milliseconds, during which the ambient magnetic fields should remain unchanged. It is recommended therefore to perform the test when the robot is stationary.