Installation Guide

This section covers the complete installation process of the MTS160 sensor, including proper mounting procedures and electrical connections.

Mounting Instructions

Left/Right Identification

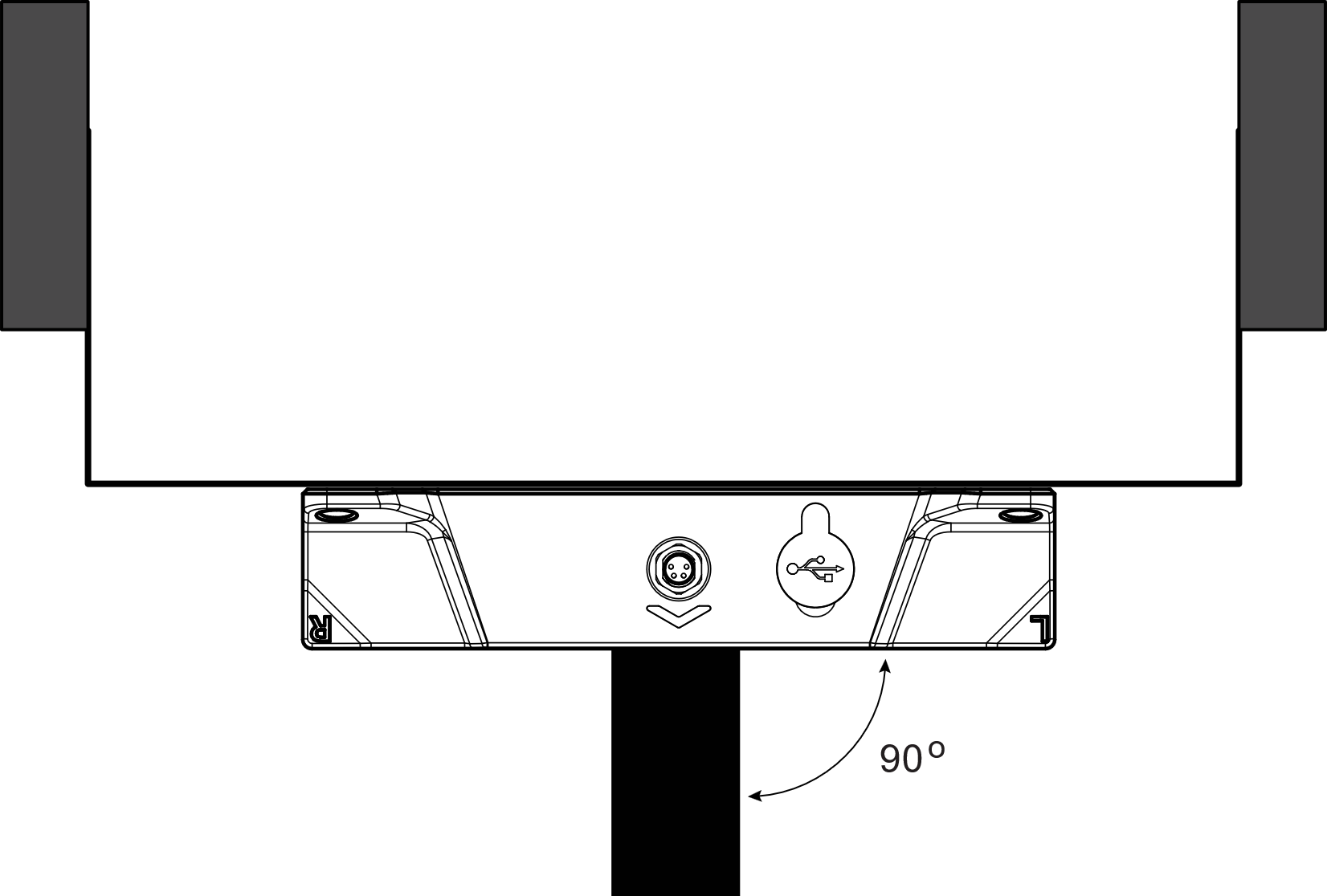

As a convention, Left and Right sides are relative to the sensor's travel direction that is pointed by the arrow-shaped LED indicator, and are identified with the L and R letters engraved on the case.

Mounting Orientation and Height

The mounting location on the robot must be as free from magnetic disturbance fields as possible.

Important Requirements

- The sensor must be fitted on the robot so that it is as perfectly parallel to the floor as possible along the length and width direction.

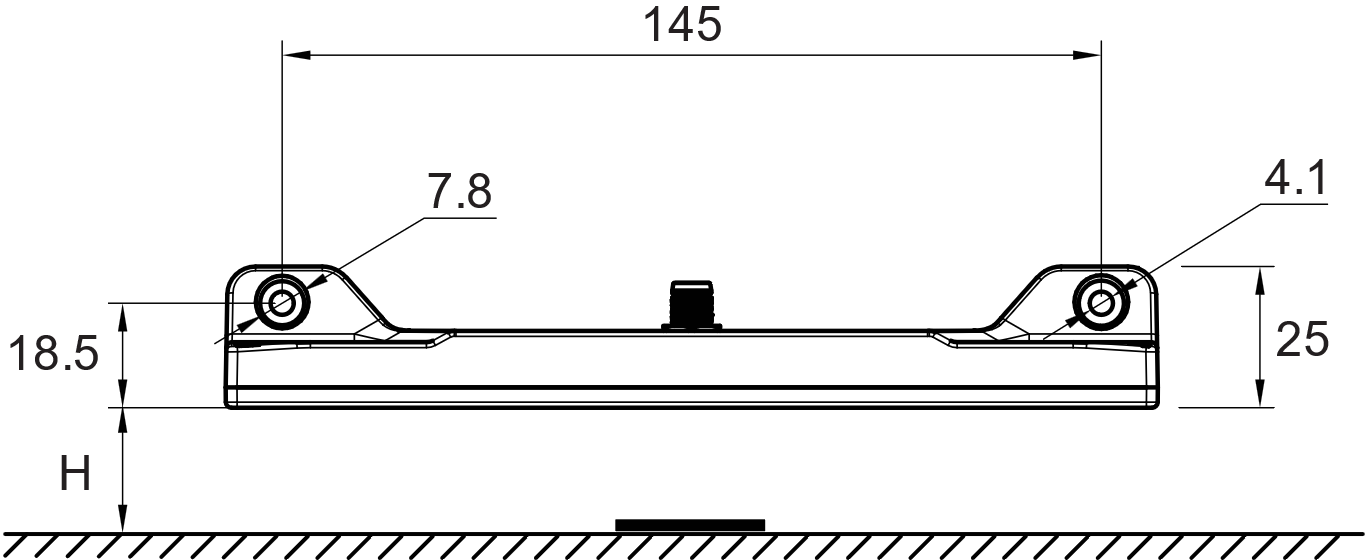

- Ideal sensor height is 20mm from the floor.

- The sensor must be fitted with the M8 connector facing upward.

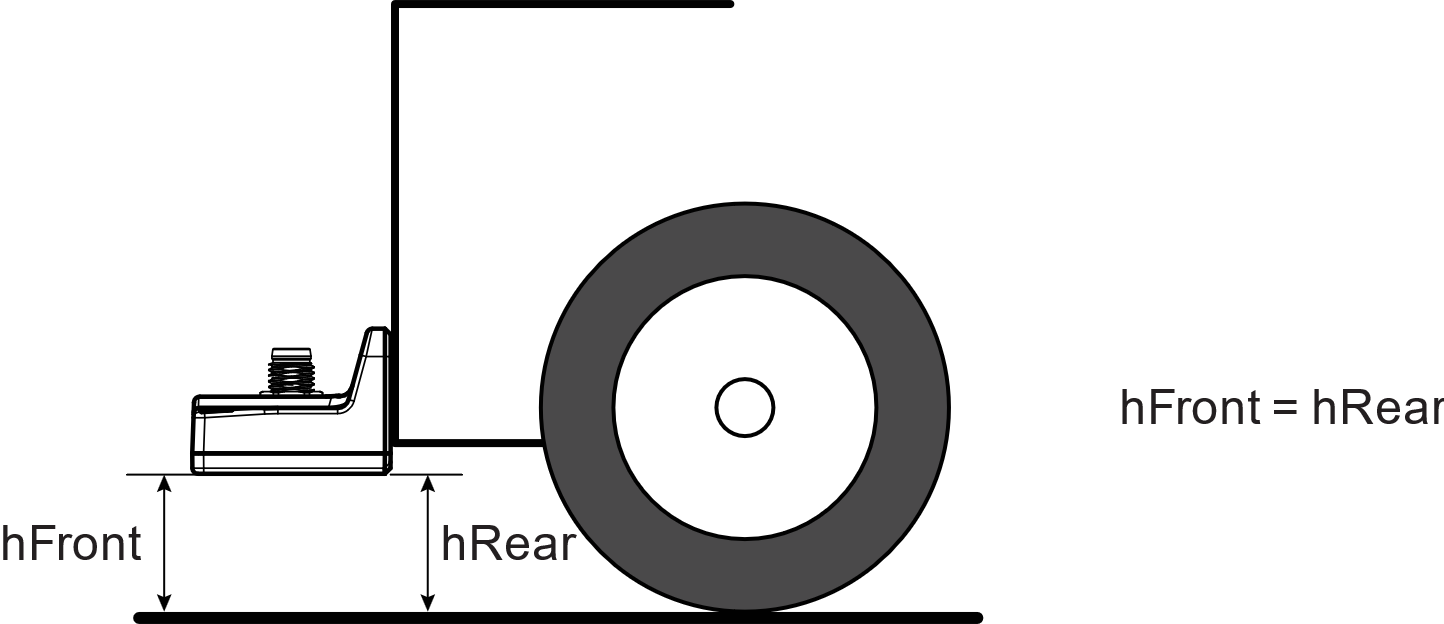

- For best performance, the sensor must remain at a constant height from the floor as the robot moves along the track.

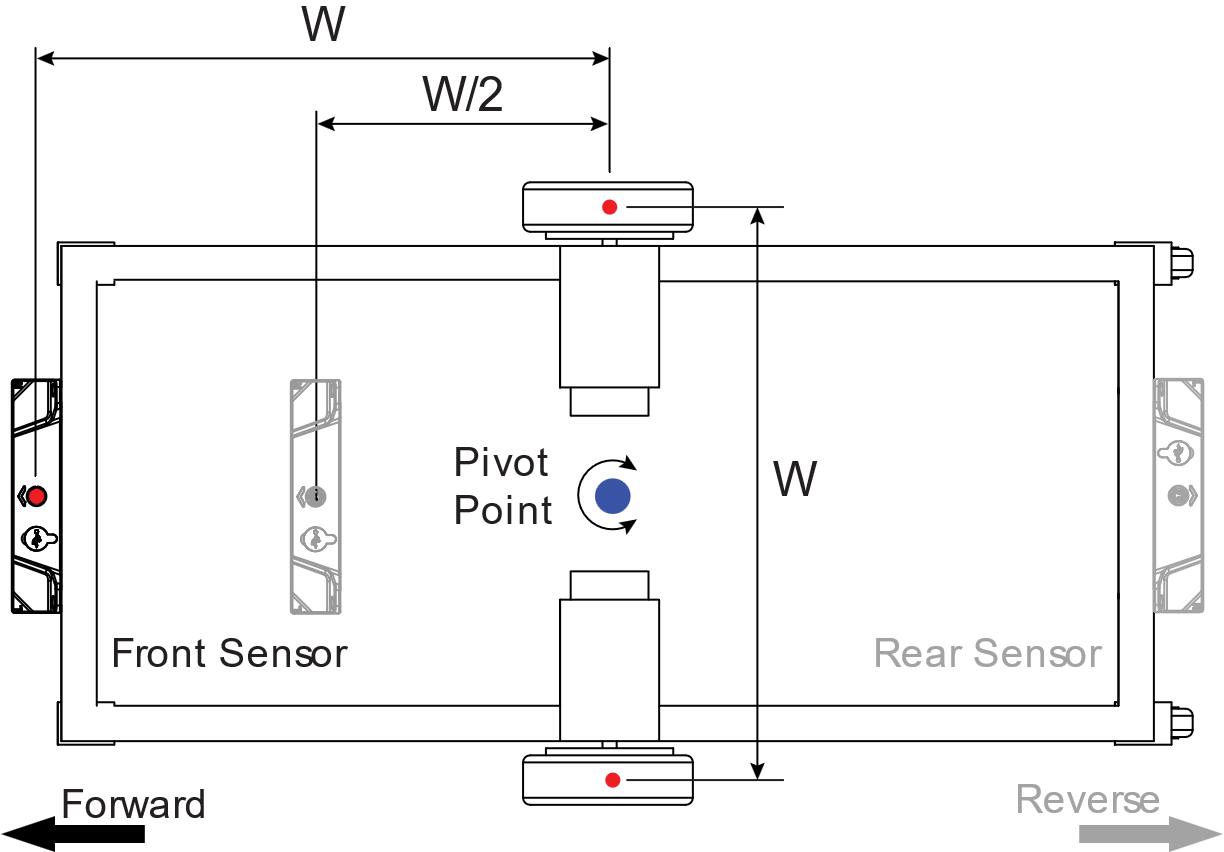

The center point of the sensor should be positioned at the Robot's center point, at a right angle to the direction of travel if possible.

Optimal Position for Steering

For robots using left/right motor-wheel arrangement the sensor must be placed at a distance relative to the wheel spacing W. To ensure that the robot can follow the magnetic path with precision and maintain control, the sensors should preferably be installed at a distance from the pivot point that falls between half the wheel spacing (W/2) and the full wheel spacing (W).

TIP

Placing the sensor too close or too far from the pivot points will make it more difficult to achieve stable and precise control.

The sensor must be placed ahead relative to the robot's travel direction. For bidirectional control, sensors must be placed at both the front and rear ends of the robot.

Physical Attachment

To mount the sensor onto the robot, follow these steps:

- Select an accessible area on the robot where the sensor will be attached.

- Refer to the dimensions indicated in the diagram and measure the spacing for the mounting holes accordingly.

- The holes for the sensor are spaced 145 millimeters apart.

- Position the holes 18.5mm higher than the desired height of the sensor above the floor.

- Drill two holes sized appropriately for M4 screws, ensuring they are perpendicular to the mounting surface for a level attachment.

- Align the sensor over the area, matching its mounting holes with those on the robot.

- Insert M4 stainless steel screws through the sensor's holes into the robot's holes.

WARNING

Stainless steel is preferred as it avoids the risk of magnetization, which could interfere with the sensor's functionality.

- Tighten the screws to secure the sensor in place, making sure it's firm but not overly tight to prevent any damage.

Electrical Connections

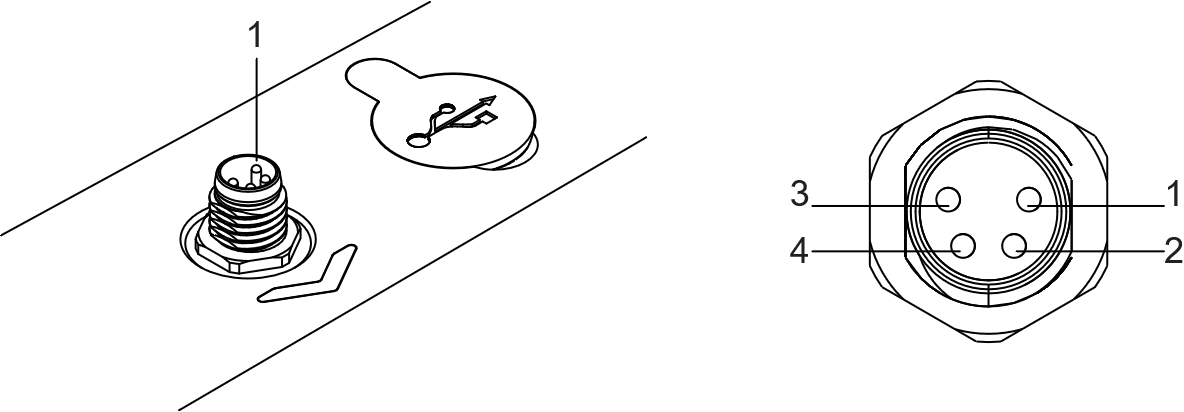

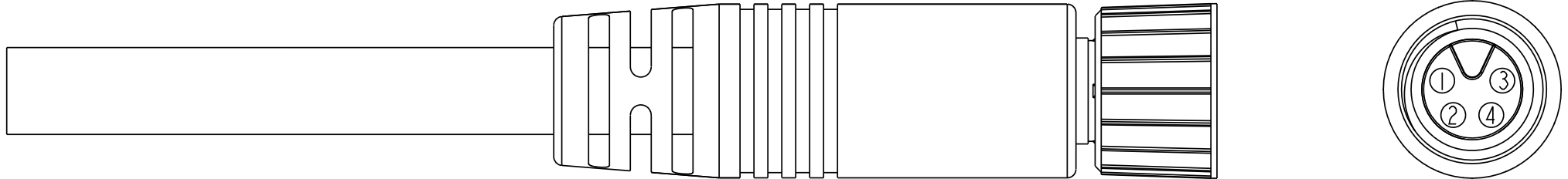

M8 Connector Pin Assignment

| Pin Number | Signal | Description | Wire Color |

|---|---|---|---|

| 1 | VIN+ | +5 to +28V Power Supply | Brown |

| 2 | CANH/RS232Tx | Data Signal 1 | White |

| 3 | GND | Power Supply Ground | Blue |

| 4 | CANL/RS232Rx | Data Signal 2 | Black |

Power Supply Requirements

Important Safety Notes

- The sensor must be connected to a stable voltage supply between 7V and 30V DC and capable of sourcing at least 2W power.

- Always use the system's main power switch to turn it on or off.

- Do not connect the M8 connector while the power is on. Always apply power after the connector is inserted.

Note

When the sensor is connected to a PC or smartphone via the USB port, it will be powered on from these devices if there is no power on the M8 cable.